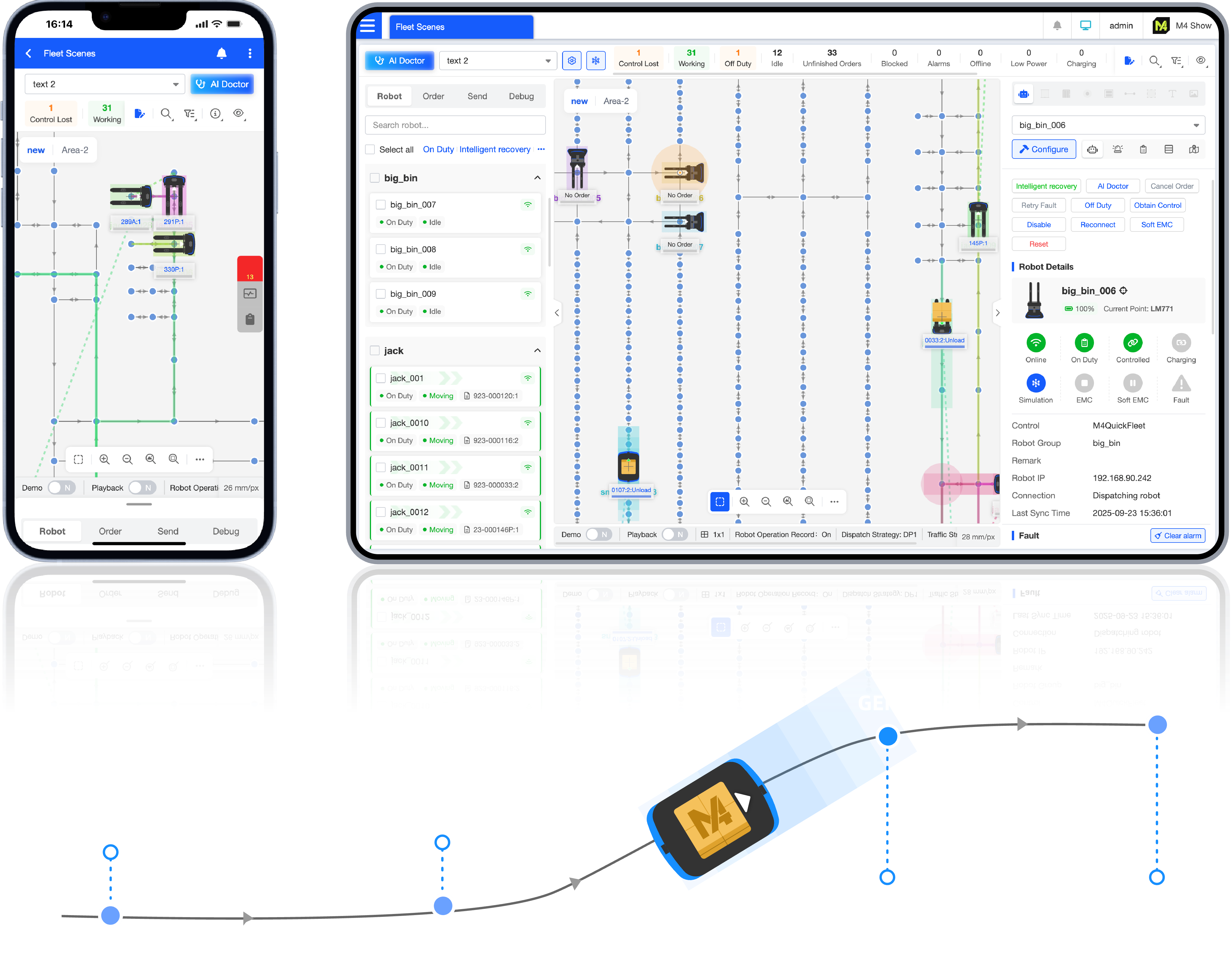

Management System

A dispatch system is inherently complex. Its complexity is shaped not only by the vendor's development capabilities, but also by the diversity of customer requirements, the degree of demand, and—being a high-tech product—the maturity of the underlying technologies.

In discussions with users, the most common expectation is 'intelligence'. However, the meaning of 'intelligence' is broad, and sometimes even contradictory. For some users, 'intelligence' means powerful functionality: their projects are complex, with multiple robot types and diverse workflows, and they expect the system to handle all kinds of transport tasks.

For others, 'intelligence' means ease of use: minimal setup, minimal daily maintenance, ideally a system that can run robots 24/7 with little to no human intervention. 'Powerful functionality' and 'ease of use' are often conflicting priorities.

Similarly, achieving the 'optimal' result usually requires higher computational effort, latency, and expensive hardware—contradicting low-cost expectations. And above all, these demands often conflict with 'stability.' No product is ever 100% stable; the more features and complexity a system carries, the harder it is to maintain stability. This isn't merely a matter of capability, but about the current stage of technological development—it is not a matter of 'the bolder the ambition, the greater the output.'

For non-expert users, it is difficult to clearly define their needs for a dispatch system at the start of a project. During product selection and related decisions (such as business process planning and on-site traffic flow), misunderstandings can easily arise, leading to losses later. A common mistake is to oversimplify the problem or to overestimate the intelligence of robots and dispatch systems. Just as one must spend time learning to use a computer or office software, implementing robots and dispatch systems also requires a thorough understanding of the product. Otherwise, whether expectations are overly optimistic or overly pessimistic, users ultimately need to bear the consequences.

The reality is: today's robots and dispatch systems are neither as 'intelligent' as some imagine, nor as unreliable as others fear. By balancing requirements with product capabilities, in most scenarios, robots and dispatch systems can meet customer needs and deliver a superior ROI compared with other approaches.