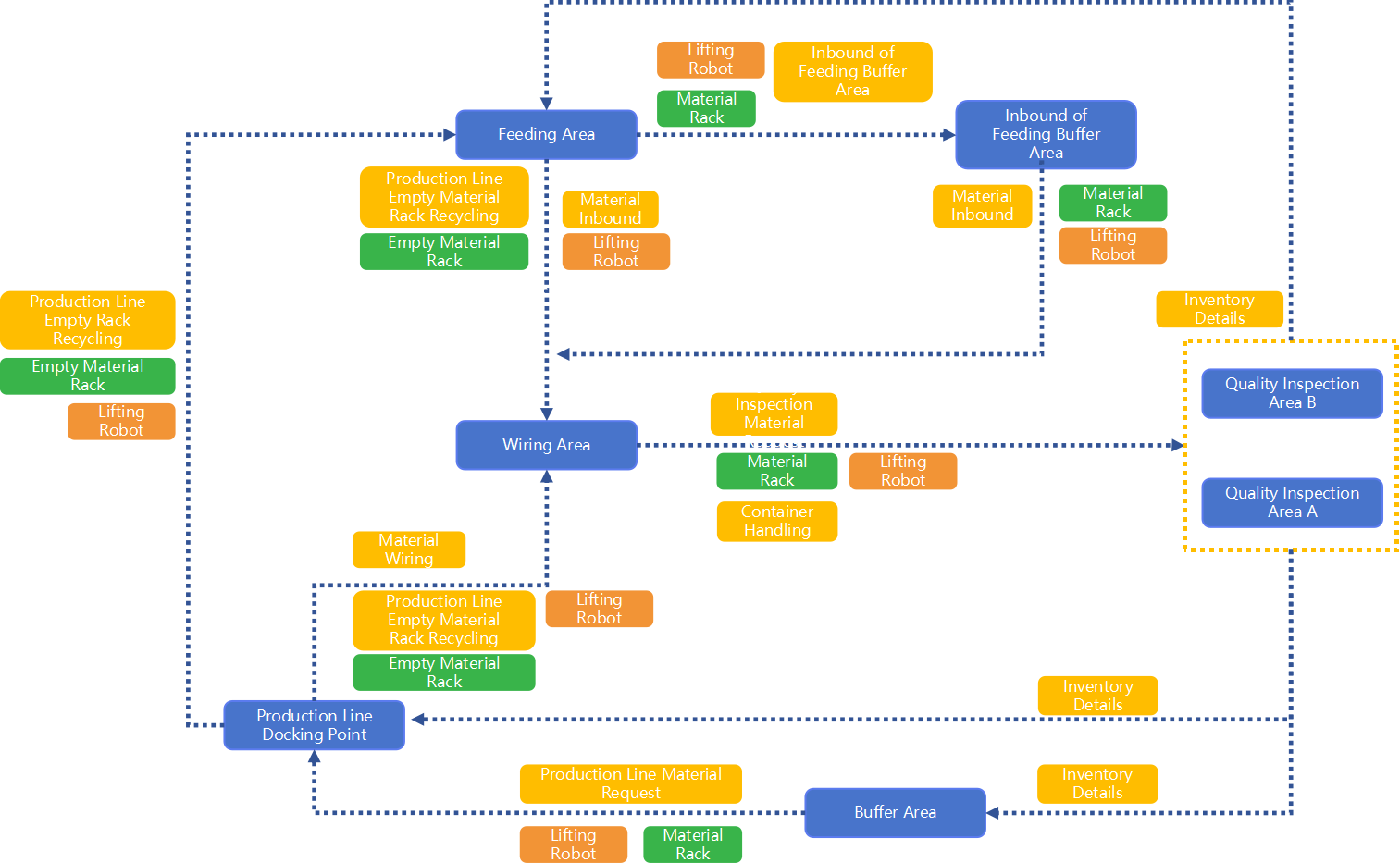

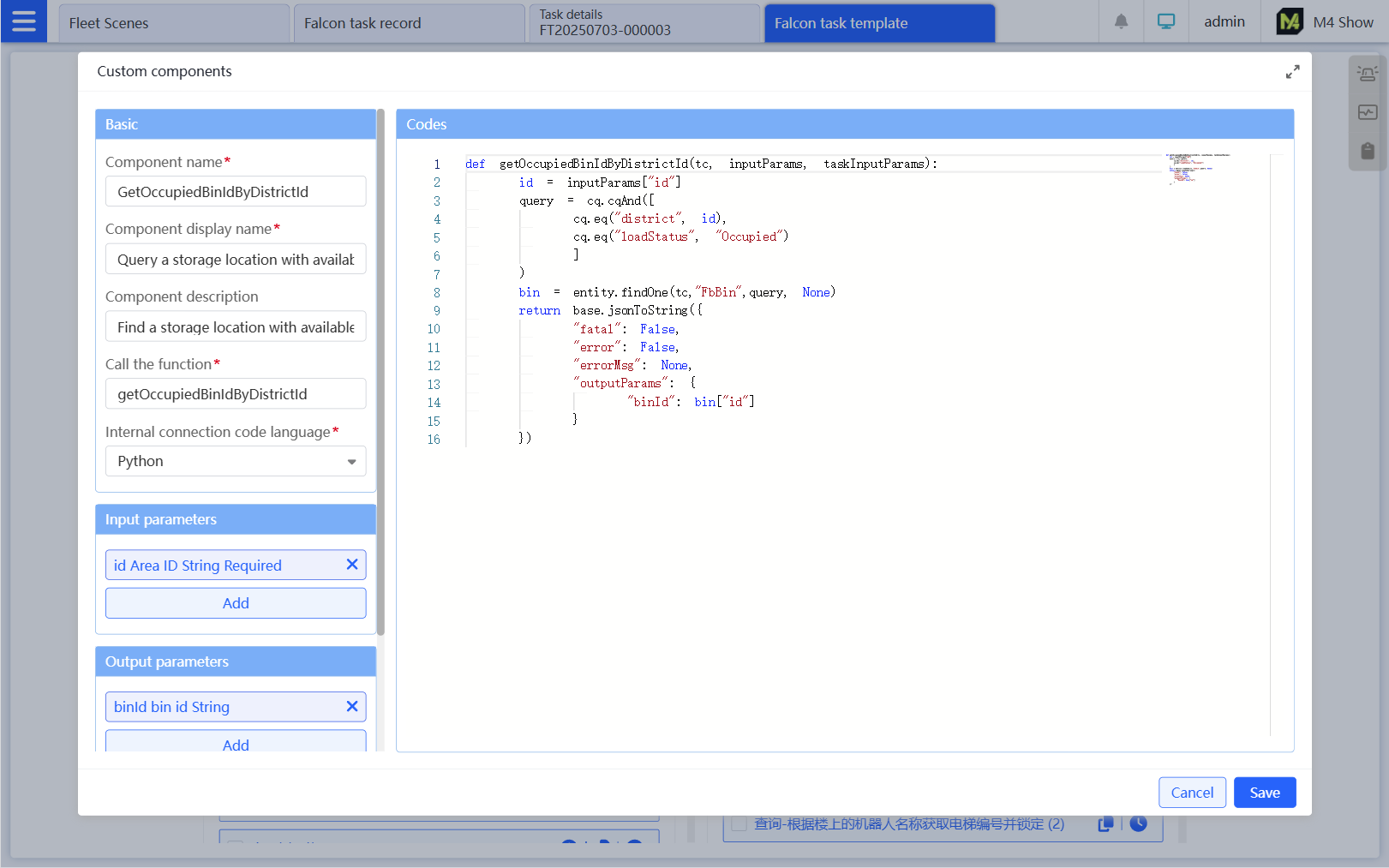

Robot dispatching can only achieve relatively standard functions, such as robot control, order dispatch, path planning, traffic control, and management of key devices like doors and elevators. However, actual business requirements are often non-standard, especially in industrial scenarios where each site's logistics needs are highly differentiated. M4 Falcon Task extends system capabilities through Python scripting and integrates with M4 QuickFleet, enabling visual orchestration of business processes to realize various non-standard requirements. For example, interacting with PLCs such as roller lines before picking up goods, notifying a third-party system after unloading, choosing different destinations based on device availability, or customizing complex storage bin selection logic according to cargo types.

In addition, with advanced features such as progress monitoring, global pause, fault recovery, and crash recovery, Falcon Task makes business operations more transparent and stable.

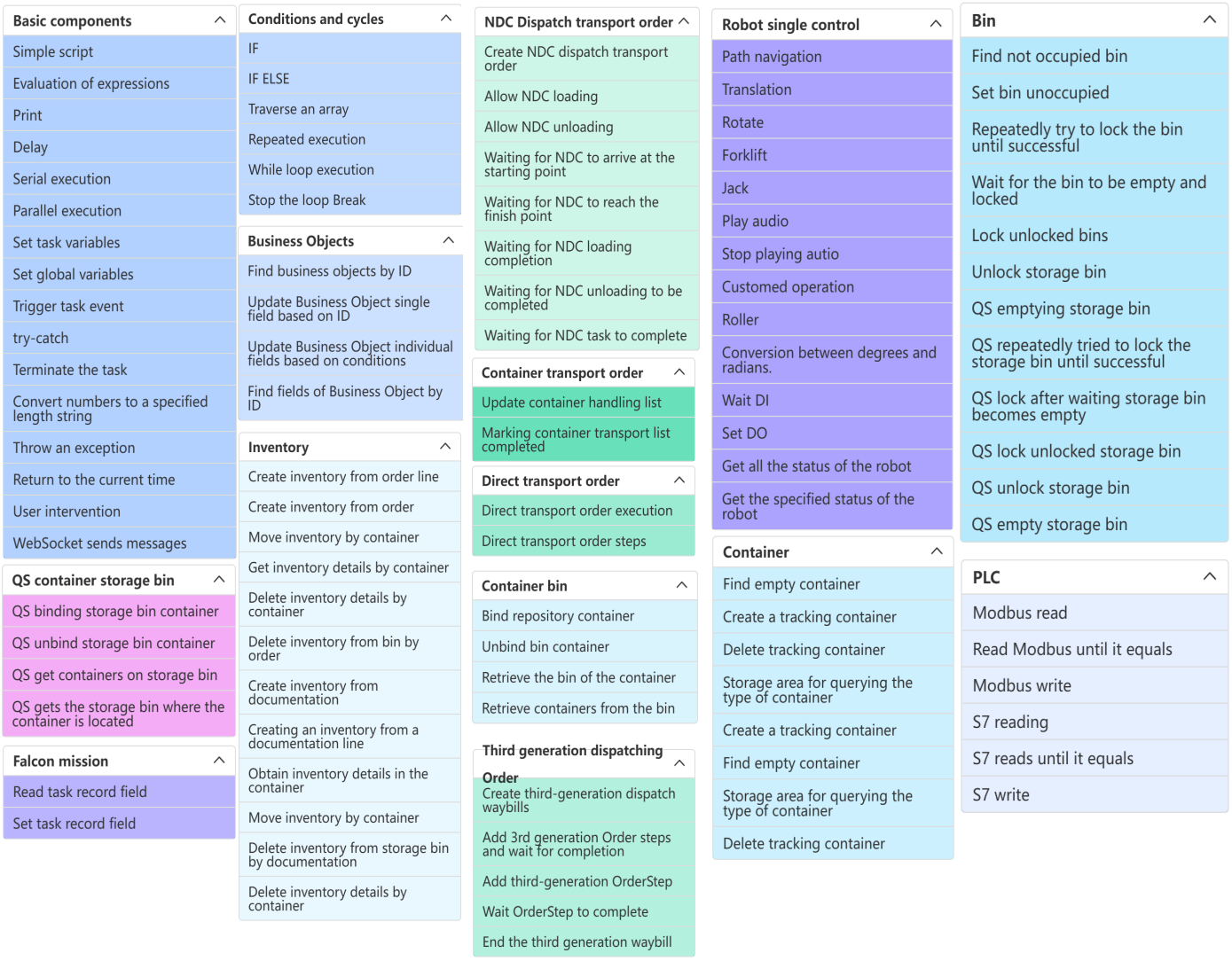

Falcon Task is a low-code task engine within the M4 system. It supports editing task action sequences through a visual interface, allowing users to quickly build complex business flows in a 'building block' style. It not only enables point-to-point transport but also handles complex business processes such as loop processing, parallel processing, multi-point transport, multi-robot collaboration, system interaction, device control, and warehouse inventory logic, like scheduled loading/unloading, replenishing empty pallets, and PLC device integration.